| Product Name | Sodium Persulfate |

| Cas Number | 7775-27-1 |

| Formula | Na2S2O8 |

| Molar Mass | 238.10 g/mol |

| Pub Chem Cid | 24475 |

| Drug Bank | DB11495 |

| Chem Spider | 22843 |

| Bioavailability | Not available |

| Protein Binding | Not available |

| Metabolism | Not available |

| Elimination Halflife | Not available |

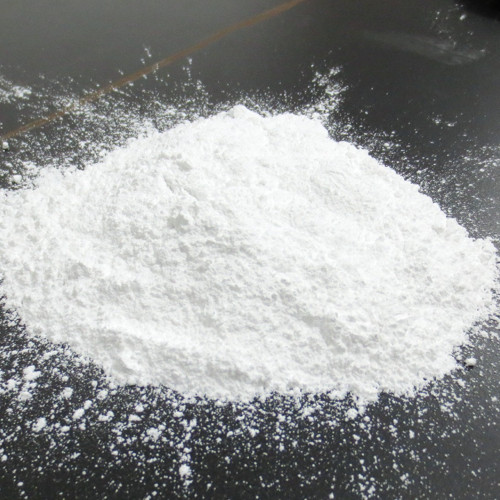

What is Sodium Persulfate and what are its primary uses?

Sodium persulfate (Na2S2O8) is a white, crystalline salt known for its strong oxidizing properties. It is widely used in various industrial applications, including polymerization, water treatment, cleaning and etching of metals, and as a bleaching agent in hair lightening products. Its powerful oxidizing abilities make it highly effective for initiating chemical reactions, such as in the polymerization of monomers like styrene and acrylates in the plastics and rubber industries. In electronics manufacturing, sodium persulfate is used as an etchant for printed circuit boards, removing excess copper to create precise pathways. The compound’s versatility and high reactivity make it a valuable tool across diverse sectors.

How is Sodium Persulfate used in the polymer industry?

In polymer manufacturing, sodium persulfate is commonly used as an initiator in the free radical polymerization process. This process involves initiating a chemical reaction that forms free radicals, which then propagate to join monomer units, forming polymers. Sodium persulfate efficiently initiates the polymerization of materials like styrene, butadiene, and acrylates, producing polymers that are the building blocks for plastics, rubber, and synthetic fibers. By controlling the rate of polymerization and the structure of the polymer, sodium persulfate ensures consistent quality and properties in the final product. Its reliability and high effectiveness as an initiator make it a popular choice in large-scale polymer manufacturing.

What safety precautions should be taken when handling Sodium Persulfate?

Sodium persulfate is a strong oxidizer and can cause irritation to the skin, eyes, and respiratory system. Direct contact with sodium persulfate may lead to skin burns, while inhalation of its dust can cause coughing, shortness of breath, and throat irritation. It’s essential to handle this compound in well-ventilated areas and wear appropriate protective equipment, such as gloves, safety goggles, and dust masks, to avoid direct exposure. Additionally, sodium persulfate should be stored in a cool, dry place away from flammable or combustible materials, as it can accelerate combustion in the presence of organic materials. In case of accidental contact, immediate flushing with water is advised, and medical attention should be sought if irritation persists.

How does Sodium Persulfate work as an etchant in electronics manufacturing?

Sodium persulfate is used as an etchant in the production of printed circuit boards (PCBs) due to its ability to dissolve metals, particularly copper. When applied to a PCB, sodium persulfate selectively removes copper from unwanted areas, leaving behind the desired circuit pattern. This process is essential for creating precise and functional circuitry in electronic devices. Sodium persulfate is favored over other etchants like ferric chloride because it produces a cleaner etch with fewer residues and less environmental impact. Proper control of concentration, temperature, and exposure time ensures an effective and uniform etching process, which is crucial for high-quality electronic components.

What are the environmental impacts of Sodium Persulfate, and how is it managed in waste treatment?

Sodium persulfate, as a strong oxidizing agent, poses certain environmental risks, particularly to aquatic life if it contaminates water sources. High concentrations can disrupt the balance of aquatic ecosystems, as it may oxidize organic matter and reduce oxygen levels in water. In waste treatment, sodium persulfate must be neutralized before disposal to prevent such environmental hazards. Common neutralization methods involve reducing agents like sodium thiosulfate, which deactivate its oxidative properties, rendering it less harmful. Many industries follow strict regulatory guidelines for handling and disposal, ensuring sodium persulfate does not enter natural water systems in reactive forms.

How is Sodium Persulfate used in soil and groundwater remediation?

Sodium persulfate is used in environmental remediation to treat contaminated soil and groundwater through a process called in-situ chemical oxidation (ISCO). When injected into contaminated areas, sodium persulfate generates free radicals, which break down organic pollutants, including petroleum hydrocarbons, pesticides, and other hazardous chemicals. This oxidation process turns these contaminants into non-toxic byproducts like carbon dioxide and water. Sodium persulfate’s effectiveness in degrading persistent organic pollutants makes it a valuable tool for environmental cleanup efforts, especially at industrial sites with long-standing pollution issues. Careful control of dosage and monitoring are required to optimize the remediation process while minimizing impact on the surrounding environment.

What makes Sodium Persulfate a preferred bleaching agent in cosmetics and hair lightening?

Sodium persulfate is widely used as a bleaching agent in hair lightening products because of its strong oxidative properties, which enable it to break down the natural pigments in hair (melanin) and produce a lighter color. Unlike gentler oxidizers, sodium persulfate works rapidly, which allows for efficient bleaching in a relatively short time. However, its potency requires cautious handling, as it can be harsh on the skin and hair. Formulations with sodium persulfate often include conditioning agents to help mitigate potential damage and reduce irritation. Due to the strength and speed of sodium persulfate in hair processing, it remains a key component in professional-grade hair lightening products.

Can Sodium Persulfate pose health risks to workers in industrial settings?

Yes, sodium persulfate can pose health risks, particularly in workplaces where it is handled frequently or in large quantities. Inhalation of sodium persulfate dust can lead to respiratory issues, including coughing, shortness of breath, and, in severe cases, asthma-like symptoms. Skin contact may cause irritation or burns, and prolonged exposure could lead to dermatitis. Industries that use sodium persulfate often implement stringent safety protocols to protect workers, such as ensuring proper ventilation, using closed systems, and providing protective clothing and respiratory masks. Routine monitoring and adherence to safety guidelines help minimize health risks associated with sodium persulfate exposure.

What are the advantages of using Sodium Persulfate in water treatment?

In water treatment, sodium persulfate is an effective oxidant for removing pollutants and disinfecting water. It can degrade organic compounds, including phenols, chlorinated solvents, and other contaminants that traditional treatment methods might not effectively eliminate. Sodium persulfate’s ability to generate sulfate radicals—highly reactive species—enhances its oxidizing power, enabling it to break down complex pollutants into simpler, less harmful substances. Its use in water treatment not only improves water quality but also reduces potential health risks associated with contaminated water. Sodium persulfate is particularly useful in advanced oxidation processes (AOPs), which are designed to address complex wastewater treatment needs.

Are there alternatives to Sodium Persulfate for industrial oxidation and etching?

Yes, alternatives to sodium persulfate are available, though each has its pros and cons depending on the application. For etching in electronics, ferric chloride and ammonium persulfate are alternatives, but sodium persulfate is often preferred due to its cleaner etching properties and ease of waste management. In polymerization, potassium persulfate can serve as an initiator, although it may not provide the same efficiency or control over polymer characteristics as sodium persulfate. In water and soil treatment, hydrogen peroxide and ozone are sometimes used as oxidants, but sodium persulfate’s stability and specific reactivity make it a favored choice in certain remediation projects. While sodium persulfate remains popular, alternatives are chosen based on factors like cost, environmental impact, and desired outcomes.